- FeatheredEdge

- New member

Offline

Offline - Registered: 3/19/2016

- Posts: 3

Drilling the safety selector hole question

First off, I would like to thank Broken Arms for the absolute work of art that I received yesterday. This 80% .308 lower is way more than I expected.

Now, to my question about drilling the selector hole. Actually I need to know if the hole needs to be centered exactly over where the detent protrudes into the selector hole. I have a Jig from another manufacturer that was supposed to be a "universal jig" that I used to cut a different 80% .308 lower. when I finished, I found that the selector detent is at about 7 o clock position. the safety does not work right.

I penciled the centerline of the safety selector detent hole on the side of my new BA lower and assembled the jig to the lower. I'm seeing the same thing with this jig.

Can anyone tell me where the detent hole should be, I'm guessing it should be centered in the hole that I drill for the safety selector. I will buy a new jig if needed, just wanted to be sure before I spent the cash.

Thanks,

FE

- scorpiusb

- Member

Offline

Offline

- From: Alabama

- Registered: 2/28/2016

- Posts: 18

Re: Drilling the safety selector hole question

Sounds like the jig was made faulty... You've already got one receiver that doesn't work. I'd be getting the .308 jig BA makes, for sure...

Found a schematic on AR15.com. It shows it centered... Scroll a little over 1/2 way down the page...

Last edited by scorpiusb (3/19/2016 1:37 pm)

Bart

- FeatheredEdge

- New member

Offline

Offline - Registered: 3/19/2016

- Posts: 3

Re: Drilling the safety selector hole question

Thanks Bart.

I checked a couple solid works drawings as well. It looks like I will be ordering up a jig.

- •

- Mike

- Moderator

Offline

Offline

- Registered: 11/01/2013

- Posts: 122

Re: Drilling the safety selector hole question

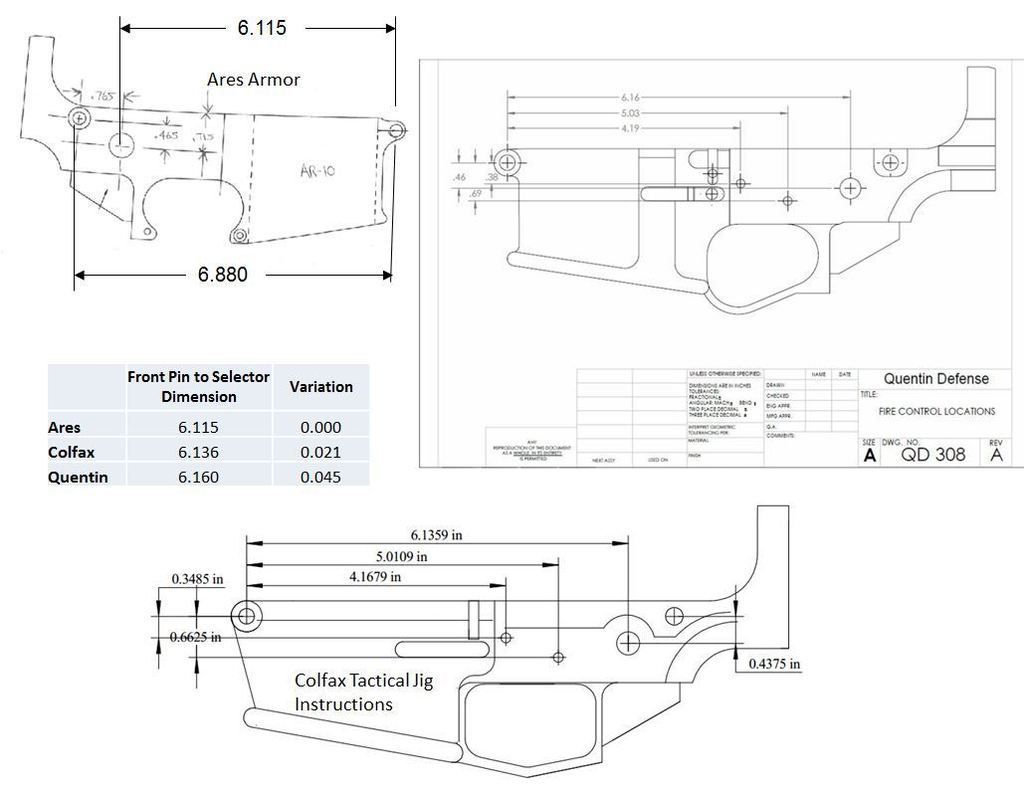

When it comes to the 308 platform, its rarely the same dimension from manufacturer to manufacturer. I'm guessing DPMS dimensions have adjusted over the many years that they made the LR-308. The distance of the 3 hole pattern moving together front or back will not affect the function of the firearm. (as long as its a little difference).

But that little difference will affect the position of the safety because the safety detent was already put in by the manufacturer of the lower. So you ALWAYS use the dimensions the manufacture gave you.

The most important thing is that the 3 holes (hammer, trigger, safety) stay in relation to each other.

Here is a pic I located on a message board a year ago.

- Mike

- Moderator

Offline

Offline

- Registered: 11/01/2013

- Posts: 122

Re: Drilling the safety selector hole question

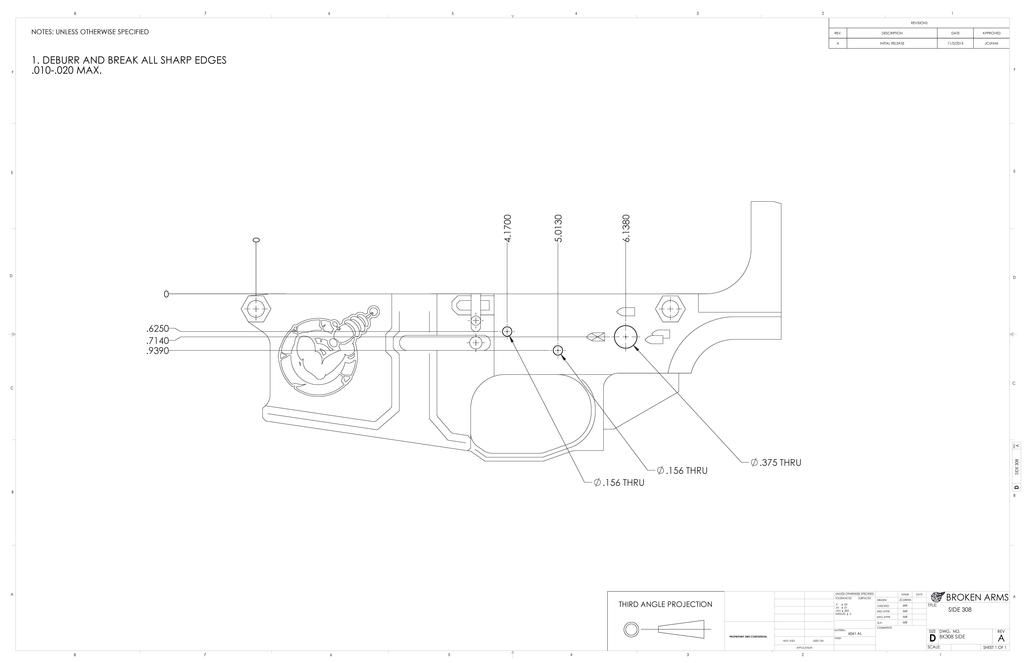

Here is our print. (6.138)

- Mike

- Moderator

Offline

Offline

- Registered: 11/01/2013

- Posts: 122

Re: Drilling the safety selector hole question

Also, Thank You for bringing these type of questions up in the message board. 308 is a f*** mess when it comes to matching parts. And these types of discussions help others understand building their firearm.

- scorpiusb

- Member

Offline

Offline

- From: Alabama

- Registered: 2/28/2016

- Posts: 18

Re: Drilling the safety selector hole question

No worries FE, unfortunately there aren't a lot of images showing the location of the safety detent hole location, and so far none I could copy.

Nice pictures Mike, do you have any showing the relationship between the detent hole and the safety selector hole?

Bart

- Mike

- Moderator

Offline

Offline

- Registered: 11/01/2013

- Posts: 122

Re: Drilling the safety selector hole question

I dont have pics. But the detent and safety are the same location 6.138. Since that was the original question, I should have addressed that.. haha sorry.

- scorpiusb

- Member

Offline

Offline

- From: Alabama

- Registered: 2/28/2016

- Posts: 18

Re: Drilling the safety selector hole question

Bart

- FeatheredEdge

- New member

Offline

Offline - Registered: 3/19/2016

- Posts: 3

Re: Drilling the safety selector hole question

Since I last posted, I was able to mock up my BA .308 lower in my existing drilling jig. I lightly scribed where the hole for the safety detent would be drilled and it seems that it will align correctly with the detent hole. The previous lower (not from BA) is some kind of weird 1/2 &1/2 design where some features were direct from the AR15 print and some were from the .308 prints. Examples are the takedown detent hole is drilled from the buffer end instead of up from the bottom and requires a special longer detent spring. The bolt release uses the same roll pin as the AR15 instead of the threaded pin which makes the 308 bolt release lever sloppy since the hole in it is for the threaded pin and is slightly larger than the pin. The outside was made to look more like a large AR15 lower. I write this to reinforce Mikes comment above stating that 308 is a f*** mess when it comes to matching parts.

That said, my existing jig seems to index correctly with the BA lower and will most likely work, but I am still leaning towards the BA jig because it requires less set up and removes more metal before the milling step which will be far easier on the mills and the drill press - and me.

Mike,

Can you tell us where you are at with the .308 top plates being ready to sell?

Are you planning on producing uppers by any chance. Or could you recommend any that would be as high quality with the same attention to detail that you put into your lowers?

- •

1

1